Electrical Subpanel Upgrade

Expand your home’s circuit capacity with a modern, safe subpanel. Whiting Electrical Services provides expert electrical subpanel upgrades in Greenville, NC for workshops, additions, and more.

Professional Electrical Subpanel Upgrade in Greenville, NC

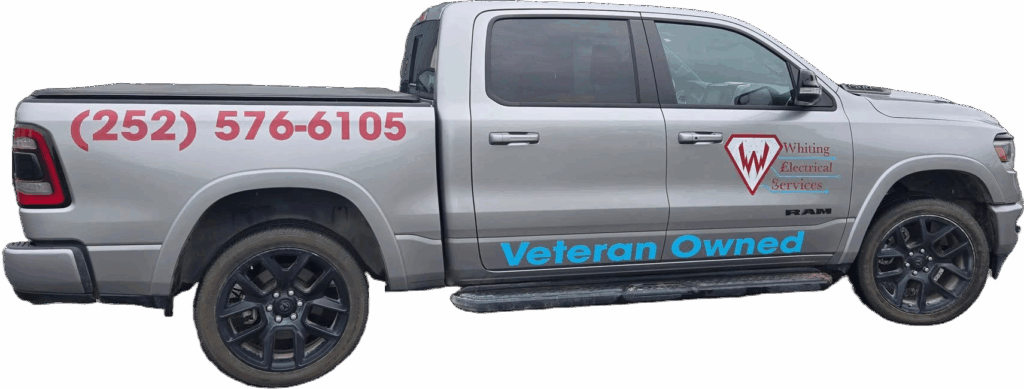

An electrical subpanel upgrade can provide the additional circuits and capacity needed for a home addition, workshop, or detached garage. It expands your system’s capabilities without requiring a full main service replacement. At Whiting Electrical Services, we specialize in upgrading existing subpanels to larger, safer, and more capable units. Our licensed electricians ensure your new subpanel is correctly sized and wired to meet all code requirements. As a company owned by a veteran, we value precision and safety in every installation. Our commitment to excellence is reflected in our A+ BBB rating. Trust us to enhance your electrical system with an upgrade backed by our Lifetime Craftsmanship Warranty.

I needed to have my generator serviced and Brad was super nice and provided extremely fast service! I called and they were here the next day ready to go. Excellent communication about when you can expect them to arrive and a smooth process overall. Highly recommend them for all your electrical and generator needs!!

There were issues with a newly installed ceiling fan, so I called Brad at Whiting Electrical. He and his technician were extremely professional, thorough, and determined to find the source of the issue. They took the time to make sure everything was repaired and installed safely. I will definitely call them for any future electrical work. They’re ten times better than any big-name electric company I’ve used in the past.

Brad was truly amazing! He stepped right in and got the job done with just a few days' notice. I would not have been able to sale my home without him. He went above and beyond to help me. Words can't thank him enough!!! If you want the work done professionally and complete call Brad!!!

Absolutely recommend!! Brad was beyond helpful, reasonable and fair! We will definitely be using my him for future jobs 🙂

Brad Whiting owner of Whiting Electrical was very knowledgeable and helpful. He explained everything about what he was doing to check my outlets. He also gave me some advice and tips on how to make sure that I don’t have any problems with my outlets. He also gave me information about the upcoming changes to the power codes. Definitely would recommend Whiting Electrical .

Great work and great service! Will be my first call for any electrical work going forward.

Needed electrical work for dishwasher installation, called and set up a time immediately, clearly communicated and confirmed via text and email. Arrived assessed the problems, Brad (electrician) Tony (plumbing) had everything taken care of promptly, clean work, checked and made sure everything was done correctly. No complaints.

And guess what happened during attic inspection? The crew found pigeons nesting, pecking cable jackets. They rerouted lines, stapled neatly, and vacuumed debris before leaving. From my perspective the extra effort matters. My lights are steady, my wife’s mixer no longer hesitates, and the electrician even fixed a squeaky attic hatch.

Just got some recessed lights installed in my kitchen. Loved how neat and fast the work was. My kitchen feels brighter and way more cozy now. Good stuff.

To my surprise, what I thought was just a minor flickering light issue turned out to be an outdated wiring problem. They not only fixed it but also checked my entire electrical system to ensure everything was safe. The best part? No mess left behind, and they explained everything in simple terms. If I had to describe their service in one word? Awesome!

If I'm honest, I was worried about getting my wiring upgraded, but they made it stress-free. Everything works perfectly now. Highly recommend them!

There ain’t no election better in Greenville, NC! Electrical in my family home was a situation Brad took on and came out feeling unburdened and safe. Thanks Whiting Electrical Services!

I recently had the pleasure of working with Whiting Electrical, and I couldn't be happier with the service I received! Brad and his team were incredibly professional, knowledgeable, and efficient. They arrived on time, assessed the situation quickly, and provided a clear explanation of the work that needed to be done. I truly appreciate their attention to detail and commitment to customer satisfaction. If you're looking for a reliable and skilled electrical company, I highly recommend Whiting Electrical. Thank you, Brad, for your excellent service! I will definitely be calling you again for any future electrical needs.

Guess what? My generator wouldn't start for weeks, and I almost gave up. Called them, and they got it running in no time! Showed me what went wrong and how to maintain it properly. Now I'm ready for any power outage. You might find this interesting—top-tier service!

Came did the job in a timely fashion was completely professional one of the best in the trade from wat I seen would recommend him for anyone's home or business

Where We Offer Our Electrical Subpanel Upgrade Service

We proudly offer Electrical Subpanel Upgrade services headquartered in Greenville, NC. Our team travels within a 50-mile radius to deliver expert, code-compliant installations backed by a lifetime craftsmanship warranty.

5-Star Reviews

Client Satisfaction

homes inspected

Completed Service Calls

Electrical Subpanel Upgrade Service in Greenville, NC

An electrical subpanel is a smaller, secondary service panel that is fed from the main electrical panel. It serves as a localized distribution point for electricity in a specific area of your property, such as a detached garage, a large workshop, a finished basement, or a major home addition. A subpanel has its own set of circuit breakers, making it convenient to control power and reset tripped breakers in that area without having to go back to the main panel. It is a practical and common way to expand a home’s electrical system. An upgrade is necessary when an existing subpanel is old, damaged, or too small for the area’s growing electrical needs.

You may need to upgrade your subpanel for several reasons. The most common reason is that the existing subpanel is out of breaker slots, and you need to add new circuits for more outlets, lighting, or equipment. For example, if you are turning your workshop into a serious woodworking space, you will need to add several new 240 volt circuits for heavy machinery, which the original small subpanel cannot accommodate. An upgrade may also be required if the existing subpanel is an older, unsafe brand, shows signs of rust and corrosion, or has been damaged. Upgrading provides both the additional capacity and the enhanced safety of modern electrical components.

The subpanel upgrade process begins with a careful evaluation of your needs. Our electricians will assess the electrical loads in the area served by the subpanel to determine the correct amperage for the new unit. We will also inspect the feeder wire that runs from the main panel to the subpanel. The size of this feeder wire determines the maximum size of the subpanel that can be installed. If you need a larger subpanel than the existing feeder can support, we will need to run a new, larger feeder cable as part of the upgrade project. This comprehensive assessment ensures the entire system is safe and properly sized.

Our professional installation process is focused on safety and code compliance. To begin the work, we will turn off the main breaker that feeds the subpanel from the main panel. Our electricians will then carefully remove the old subpanel. The new, larger subpanel will be securely mounted in its place. We then transfer all the existing circuits to new breakers in the new panel. We ensure all connections are properly torqued and that the wiring is organized neatly. A crucial part of a subpanel installation is ensuring that the neutral and ground wires are handled correctly; unlike in a main panel, the neutral and ground bars must be kept separate and not bonded together in a subpanel.

A key difference in a subpanel installation compared to a main panel is the grounding requirement, especially for a subpanel in a detached building. A subpanel in a separate structure, like a detached garage, requires its own grounding electrode system. This typically means driving one or two new ground rods into the earth near the building and connecting them to the ground bar in the subpanel. This ensures electrical safety for that building, independent of the main house. Our electricians are experts in these specific code requirements and will ensure your upgraded subpanel is not only powerful but also fundamentally safe.

An upgraded subpanel provides significant benefits. It gives you the circuit capacity you need to fully utilize your space, whether it is for a hobby or a home business. It enhances safety by replacing older components with new, reliable breakers and ensuring the system is up to the latest electrical code. This can be especially important in areas like workshops where power tools draw significant current. A properly installed and upgraded subpanel also adds to your property’s value by showcasing a capable and professional electrical system. It is a smart investment in the functionality and safety of your home.

When you choose Whiting Electrical Services for your subpanel upgrade, you are choosing a partner dedicated to quality. As a veteran owned business, we bring a mission focused approach to ensure your project is completed correctly and efficiently. Our A+ BBB rating and reputation in the Greenville community speak to our commitment to customer satisfaction. We provide clear explanations and upfront pricing, and all of our work is backed by an industry leading Lifetime Craftsmanship Warranty. Let us help you expand your home’s electrical capabilities with a professional subpanel upgrade.

FAST RESPONSE TIMES

We answer calls quickly, return messages promptly, and schedule service without delays across the Greenville, NC area.

cRAFTSMANSHIP WARRANTY

Every job we complete is backed by a lifetime warranty that protects the workmanship on your electrical project.

TRUSTED BY GREENVILLE

We’ve handled electrical projects for major names like Mr. Beast, local businesses, and countless residents in the Greenville, NC area.

Browse Our Electrician Services in Greenville, NC

We provide a complete range of residential and commercial electrical services throughout Greenville, NC and the surrounding area. No matter the size or type of project, our licensed team delivers safe, code-compliant work with attention to detail and long-term reliability.

Easy Financing For Your Electrical Subpanel Upgrade

Whiting Electrical Services uses Wisetack Financing to make your Electrical Subpanel Upgrade seamless. Easily prequalify below or call our office at (252) 576-6105 for assistance.

- Break large projects into smaller monthly payments

- Choose from multiple term lengths that fit your budget

- Fast approval process with no hidden fees

- No impact on credit score to check your options

- Get the work done now and pay over time with confidence

Common Electrical Subpanel Upgrade Questions

Upgrading a subpanel is a common project for homeowners looking to expand their electrical capacity in a specific area. Understanding why and how this upgrade is performed is key to a successful project. Here are some of the most common questions Greenville homeowners have about electrical subpanel upgrades.

A subpanel would need to be upgraded for several important reasons, most of which revolve around capacity, safety, and age. The most frequent reason for an upgrade is a lack of capacity. An existing subpanel, perhaps installed years ago for a simple garage, may only have a few breaker slots. If you now want to convert that garage into a workshop with multiple power tools, or a home gym with a treadmill and other equipment, the old subpanel will not have enough space to add the necessary new circuits. Upgrading to a larger subpanel with more breaker slots provides the room you need to safely power your new equipment without overloading the existing circuits.

Safety is another critical reason for an upgrade. Just like main panels, some older subpanels were made by manufacturers now known for being hazardous, such as Federal Pacific Electric or Zinsco. These panels contain breakers that may not trip during an overload, creating a serious fire risk that necessitates an immediate replacement. A subpanel may also need to be upgraded if it shows signs of physical damage, such as rust from moisture exposure or evidence of overheating like melted plastic or scorch marks. Any of these conditions compromise the safety of the unit and warrant a full upgrade to a modern, safe, and reliable panel.

Finally, the purpose of the space may change, requiring an upgrade in the subpanel’s overall amperage rating. For instance, a subpanel that was installed to power a few lights and outlets in a shed might only be a 30 amp subpanel. If you decide to convert that shed into a heated and cooled office or studio, you will need significantly more power. This would require upgrading not just the subpanel box itself, but also the feeder wire coming from the main panel to a larger size capable of carrying a higher amperage, such as 60 or 100 amps. This ensures the subpanel has enough total power to supply all the new circuits it will contain.

The difference between a main panel and a subpanel lies in their source of power and their internal wiring configuration for grounding and neutrals. The main panel is the central hub of your entire electrical system. It receives power directly from the utility company’s lines via the electric meter. It is the first point of disconnection for your entire home, containing the main circuit breaker that can shut off power to everything at once. Inside the main panel, the neutral bus bar and the ground bus bar are connected, or “bonded,” together. This bond connects your home’s neutral wiring to the main grounding electrode system, which is a critical safety feature.

A subpanel, in contrast, does not receive power directly from the utility. Instead, it receives its power from the main panel through a dedicated, high amperage feeder circuit. It acts as a remote distribution center for a specific area of your home, like a garage or basement. A subpanel is protected by a large circuit breaker back in the main panel. If you shut off that specific breaker in the main panel, it will de energize the entire subpanel. This hierarchical relationship is the key functional difference; the main panel feeds the subpanel.

The other crucial difference is the internal wiring. In a subpanel, the neutral bus bar and the ground bus bar must be kept separate; they are not bonded together. The subpanel must have a separate ground bar that is connected back to the ground bar in the main panel via the ground wire in the feeder cable. This ensures that any fault current has a clear and safe path back to the main panel and to the earth ground, preventing dangerous neutral current from flowing on the grounding wires. This separation of grounds and neutrals is a critical code requirement for subpanel installations and is one of the most common mistakes made in DIY installations.

The cost to upgrade an electrical subpanel can vary widely depending on the scope and complexity of the project. A primary factor in the cost is the size and amperage of the new subpanel being installed. A larger subpanel with more circuit slots or a higher amperage rating will cost more than a smaller one. The price will also include the cost of all the new circuit breakers that will be installed in the new subpanel. If any specialized breakers are needed, such as GFCI or AFCI breakers to meet code requirements, this will also affect the material cost.

The most significant variable in the cost is often the condition of the feeder wire that runs from the main panel to the subpanel. If the existing feeder wire is large enough to support the amperage of the new, upgraded subpanel, the project is relatively straightforward and less expensive. However, if the upgrade requires a larger amperage than the existing feeder can handle, a new, thicker feeder cable must be run from the main panel to the subpanel’s location. The cost of this new wire and the labor to install it, which can be difficult depending on the distance and route it must take, can be a major part of the total project cost.

When you receive a quote from Whiting Electrical Services for a subpanel upgrade, it will be a comprehensive price covering all aspects of the job. This includes the new subpanel and breakers, any necessary feeder wire, professional labor, and the cost of the electrical permit if one is required for the scope of work. A simple upgrade of an existing 60 amp subpanel with an adequate feeder might be a few hundred dollars, while a more complex upgrade that includes running a new 100 amp feeder to a detached garage could be significantly more. We provide detailed, upfront estimates so you can make an informed decision about your project.

Adding or upgrading a subpanel is a complex electrical task that should not be attempted as a DIY project unless you have extensive electrical knowledge and experience. The risks involved are significant, both to your personal safety and to your property. Working with your home’s electrical system, especially when installing a subpanel, requires interacting with high voltage components. A mistake can easily lead to severe electric shock, electrocution, or a dangerous arc flash event. Professional electricians have the training, safety equipment, and experience to perform this work safely, and it is a risk that is not worth taking for a homeowner.

Beyond the immediate safety risks, there are numerous technical complexities and strict electrical code requirements that must be followed when installing a subpanel. One of the most critical and commonly mistaken rules is the requirement to keep the neutral and ground bars separate in the subpanel. Incorrectly bonding them can create a dangerous situation where normal operating current flows on the grounding system, potentially energizing the metal casings of your appliances. Other technical requirements include using the correct size feeder wire and breaker, ensuring proper grounding for detached buildings, and making all connections with the correct torque. Failure to adhere to these codes can create a serious fire hazard.

Furthermore, adding a new subpanel almost always requires an electrical permit from your local building authority. This work must then be inspected by a municipal inspector to ensure it is code compliant. An unpermitted and uninspected DIY installation will cause significant problems when you sell your home and could void your homeowner’s insurance policy. If a fire were to occur due to the improper installation, your insurance claim would likely be denied. For all these reasons, hiring a licensed and insured electrician from Whiting Electrical Services is the only safe and responsible way to have a subpanel upgraded or installed.

Whether a subpanel needs its own ground rod depends entirely on its location. If the subpanel is installed within the same building as the main electrical panel, such as in a basement, an attached garage, or an upstairs laundry room, it does not require its own ground rod. In this case, the subpanel’s ground bar is connected back to the main panel’s grounding system via the ground wire included in the feeder cable that powers the subpanel. The entire building shares the single, main grounding electrode system established at the main service panel, and this is sufficient to provide safety for the entire structure.

However, if the subpanel is installed in a separate, detached building, such as a detached garage, a workshop, a barn, or a pool house, then it absolutely does require its own ground rod or, more accurately, its own grounding electrode system. The National Electrical Code requires this to ensure electrical safety in the separate structure. This is because a detached building can have a different electrical potential relative to the earth than the main house, especially during a lightning storm. The local ground rods at the detached building help to dissipate any voltage differences and provide a local reference to ground, which is a critical safety feature.

When we install a subpanel in a detached building, the process involves driving one or sometimes two eight foot ground rods into the earth near the building. These rods are then connected with a copper wire to the ground bar inside the subpanel. It is important to note that this local grounding system does not replace the equipment grounding conductor that runs back to the main house in the feeder cable; both are required. This is a nuanced but crucial part of the electrical code that our licensed electricians at Whiting Electrical Services understand and implement correctly to ensure your outbuildings are powered safely.

The size of the subpanel you need, rated in amps, depends entirely on the electrical loads you plan to power from it. The first step in determining the correct size is to make a detailed list of every light, outlet, and piece of equipment that will be connected to the subpanel’s circuits. This includes both 120 volt and 240 volt loads. For example, in a workshop, you would list the overhead lighting, the general use outlets, and any specific heavy duty machines like a table saw, a dust collector, or a welder, noting the voltage and amperage requirements for each. A proper calculation is essential to avoid installing an undersized panel.

Once you have the list of loads, a licensed electrician can perform a formal load calculation based on formulas from the National Electrical Code. This calculation determines the total potential power demand of the area. Based on this calculated load, the electrician will recommend a subpanel size that can safely handle the demand with some room for future expansion. Common subpanel sizes are 60 amps, 100 amps, and 125 amps. For a simple garage with just lights and a few outlets, a 60 amp subpanel is often sufficient. For a serious workshop or a large home addition with a kitchenette, a 100 amp subpanel is more appropriate.

It is also crucial to remember that the size of the subpanel cannot exceed the capacity of the feeder wire that supplies it with power from the main panel. For example, you cannot install a 100 amp subpanel if the feeder wire is only rated for 60 amps. The breaker in the main panel that protects this feeder wire must also be sized correctly. The experts at Whiting Electrical Services can perform a thorough assessment of your needs, calculate your expected load, and recommend the appropriately sized subpanel and feeder wire to create a safe and capable expansion of your home’s electrical system.

Yes, a subpanel can technically be the same size as the main panel, but it is a common point of confusion. For example, it is perfectly acceptable to install a 200 amp subpanel that is fed from a 200 amp main panel. However, this does not mean that you have 400 amps of total capacity. The subpanel’s capacity is ultimately limited by the size of the breaker in the main panel that feeds it and the size of the feeder wire connecting the two. You would typically feed a 200 amp subpanel from a 100 amp or 125 amp breaker in the main panel, which means the subpanel can only ever draw a maximum of 100 or 125 amps, even though the panel itself is rated for 200 amps.

So why would an electrician install a subpanel with a higher rating than its feeder breaker? The main reason is the number of available breaker spaces. A 200 amp panel will have many more slots for individual circuit breakers than a 100 amp panel will. If you have a large workshop or a home addition with many different circuits for lights, outlets, and equipment, you may need the physical space offered by a 200 amp panel, even if the total power demand at any one time will not exceed 100 amps. Using a larger panel simply for the extra circuit space is a common and perfectly safe practice.

Another reason is cost and availability. Sometimes, a 200 amp panel is more readily available or not significantly more expensive than a 125 amp panel, so it makes sense to install the larger one for the added flexibility it provides for future additions. The key takeaway is that the amperage rating on the subpanel box itself only indicates the maximum current the panel’s internal bus bars are designed to handle. The actual, functional capacity of the subpanel is determined by the size of the breaker that protects it back in the main panel. An electrician at Whiting Electrical Services can help you select the right size panel based on both your power and circuit space needs.

The National Electrical Code (NEC) does not specify a maximum distance that a subpanel can be from the main panel. In theory, you can run a feeder wire to a subpanel hundreds of feet away, as long as you account for a phenomenon called “voltage drop.” Voltage drop is the gradual loss of electrical pressure, or voltage, that occurs as electricity travels along a wire. The longer the wire, the more voltage is lost. If the voltage drops too much by the time it reaches the subpanel, appliances and equipment connected to it will not receive the proper voltage to operate correctly. This can cause motors to overheat and shorten their lifespan, and electronic devices to malfunction.

To combat excessive voltage drop on a long feeder run, it is necessary to use a larger gauge wire than what would normally be required for that amperage. A thicker wire has less resistance, which reduces the amount of voltage that is lost over the distance. The NEC recommends that the total voltage drop on a circuit should not exceed 3% for the feeder and 5% total for the feeder and branch circuit combined. A qualified electrician must perform a voltage drop calculation when designing a long feeder run for a subpanel. This calculation takes into account the amperage of the subpanel, the total distance of the run, and the material of the wire to determine the correct, upsized wire gauge needed to keep the voltage drop within acceptable limits.

So, while there is no strict limit on the distance, there are practical and financial considerations. A very long feeder run will require a very large and expensive copper or aluminum cable to compensate for voltage drop, which can significantly increase the total cost of the project. When planning for a subpanel that is far from the main panel, such as for a barn or a workshop at the back of your property, it is essential to have a professional from Whiting Electrical Services design the installation. We will perform the necessary calculations to ensure your subpanel receives the proper voltage to operate safely and effectively, regardless of the distance.

Get The Best Electrical Subpanel Upgrade Near You

Schedule your professional Electrical Subpanel Upgrade in the Greenville area by using our 24/7 online booking system or by calling (252) 576-6105 today.